BlueMAX™ PLUS-Series

SCR and passive DPF system Features

- Selective Catalytic Reduction (SCR) and passive Diesel Particulate Filter (DPF) system

- BlueMAX™ PLUS 100 is ideal for Off-road application (construction, mining, material handling), BlueMAX™ PLUS 200 – On-road, BlueMAX™ PLUS 300 – Power Generation, BlueMAX™ PLUS 320 – Marine, BlueMAX™ PLUS 350 – Gantry Cranes, BlueMAX™ PLUS 420 – Locomotive industry

- EPA verified for 100-750hp engines in the off-road application (BlueMAX™ PLUS 100)

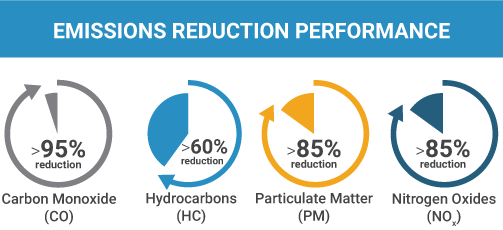

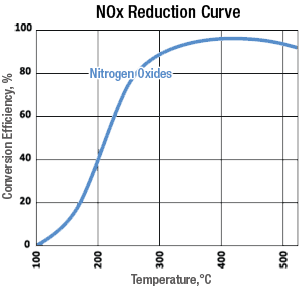

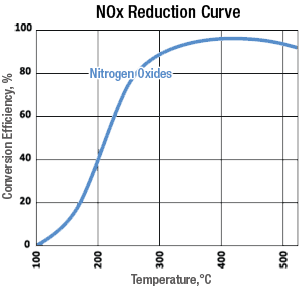

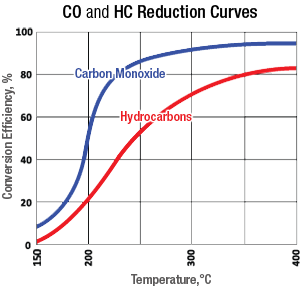

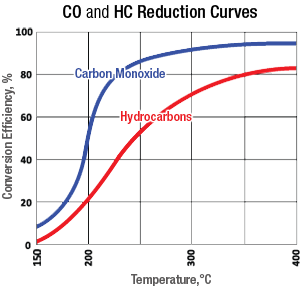

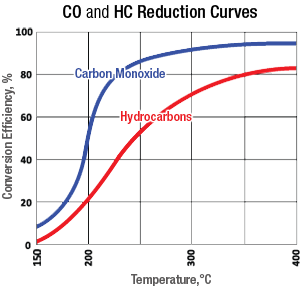

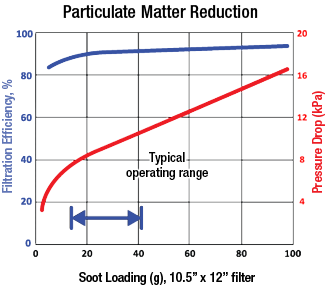

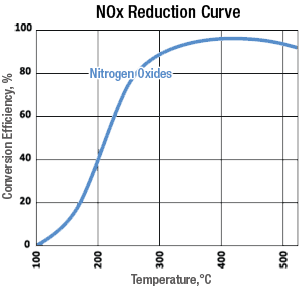

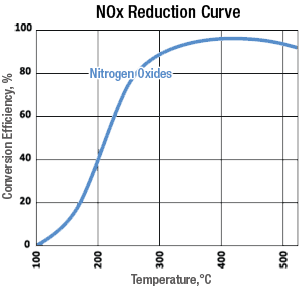

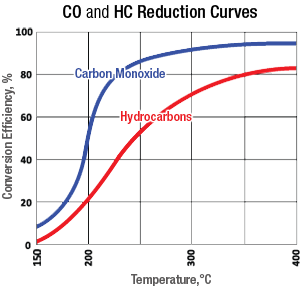

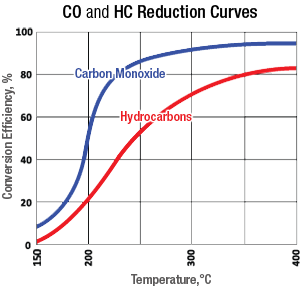

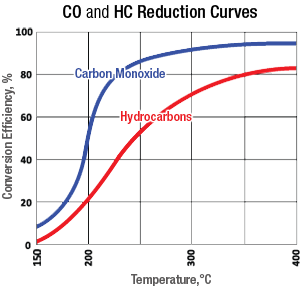

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC) and Nitrogen Oxides (NOx) emissions from your diesel engine

- Engineered to install into a tight engine compartment

- Durable design with quiet operation

- Internally insulated

- Computerized controller with 3 customizable alarms

- System maintenance intervals of 2000 to 5000 hours

- Data logging capabilities

- Colour display informing of system status and operational conditions

BlueMAX™ PLUS-Series - Technology

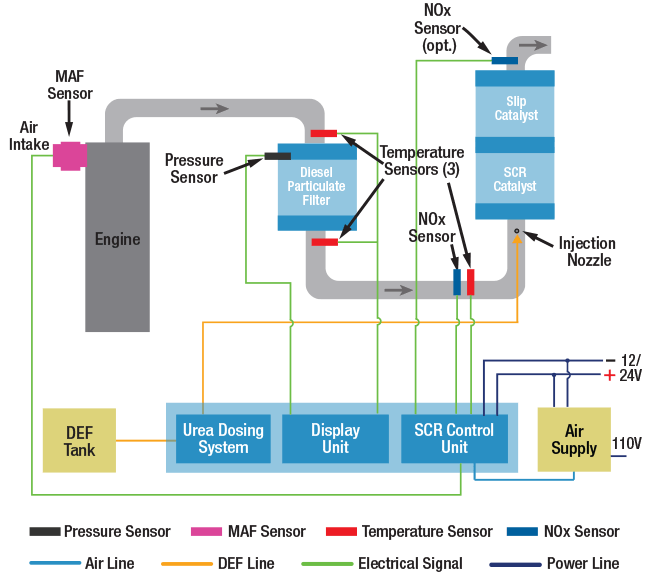

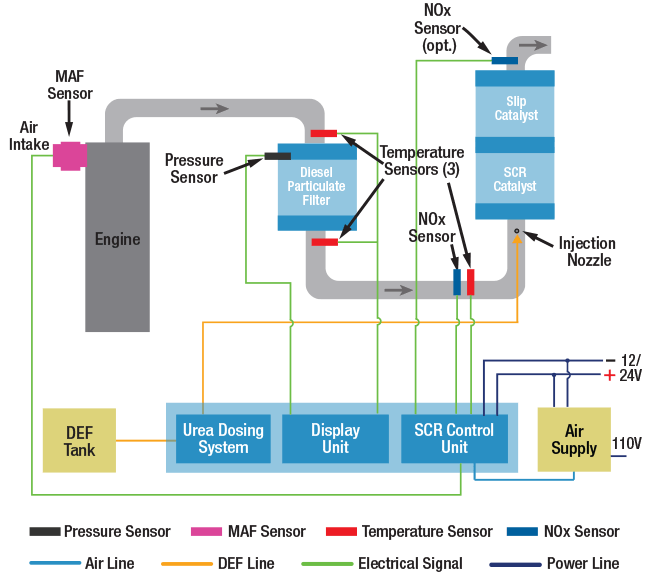

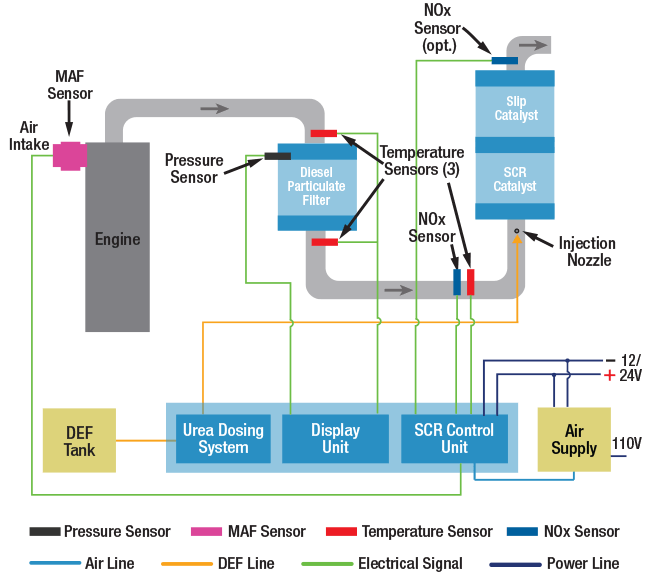

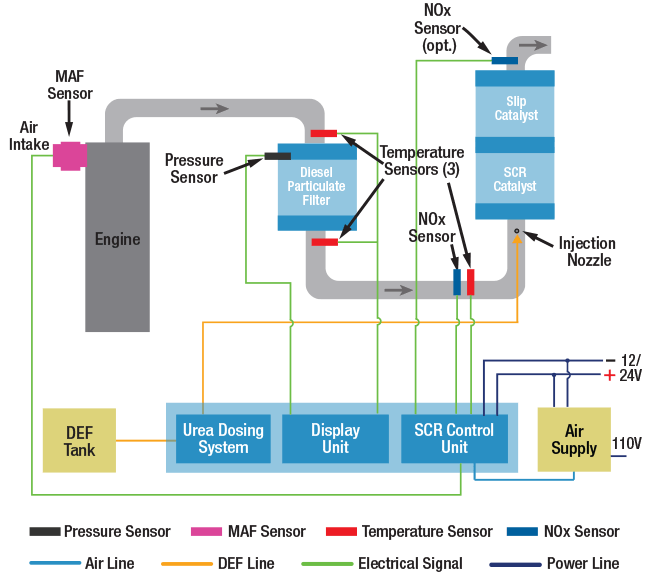

BlueMAX™ PLUS-Series System Schematic Drawing

BlueMAX™ PLUS-Series - Performance

BlueMAX™ PLUS-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ PLUS-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ PLUS-Series Standard Models (GT)

| Max. Engine Power | ||

| Model | hp | kW |

| GT5100 | 100 | 75 |

| GT5200 | 150 | 110 |

| GT5300 | 200 | 150 |

| GT5400 | 250 | 185 |

| GT5500 | 300 | 225 |

| GT5600 | 350 | 260 |

| GT5700 | 400 | 300 |

| GT5800 | 450 | 335 |

| GT5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ PLUS-Series Selective Catalytic Reduction (SCR) and Passive Diesel Particulate Filter (DPF) system is typically installed under-hood, retaining the equipment's factory appearance and operator sight-lines.

BlueMAX™ PLUS 100 - Verification

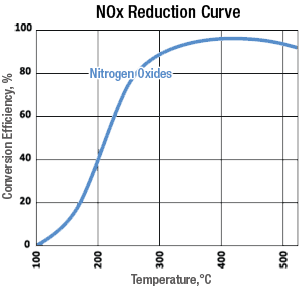

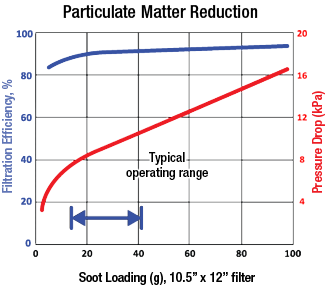

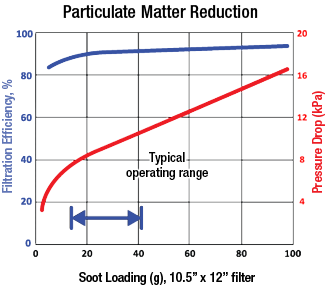

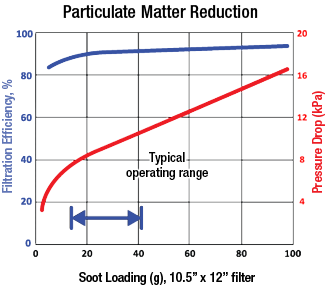

The BlueMAX™ PLUS 100 Selective Catalytic Reduction (SCR) system represents the industry’s only Nitrogen Oxides (NOx) and Particulate Matter (PM) retrofit emission control device to be commercially available to the non-road market. Nett Technologies’ BlueMAX™ PLUS 100 SCR system has been designed to reduce NOx and PM by a minimum of 85% from medium-and heavy-duty non-road diesel engines ranging between 75 and 560 kW (100-750 hp). In addition to removing NOx and PM, the system also has the added benefit of reducing Carbon Monoxide (CO) emissions by 95% and Hydrocarbons (HC) by 60%. This product is well suited for known PM2.5 and ozone nonattainment areas were controlling both PM and NOx are key factors towards adopting appropriate State Implementation Plans (SIPs) under the Clean Air Act.

The BlueMAX™ PLUS 100 system consists of a passive Diesel Particulate Filter (DPF) followed by a urea SCR system. “The BlueMAX™ PLUS 100 is a great retrofit emission control solution for non-road engines certified to Tier 1, 2 or 3 emission standards. The system is a durable and versatile emission control solution that extends the years of usage of existing construction and non-road equipment. Thanks largely to its direct-fit design, the system not only meets the latest regulations but is highly efficient in its operation.

Criteria to achieve emission reductions

The following criteria must be met in order for appropriately retrofitted engines to achieve the aforementioned emission reductions:

- Baseline engine must be in a certified configuration and operating on fuel with less than 15 ppm sulfur.

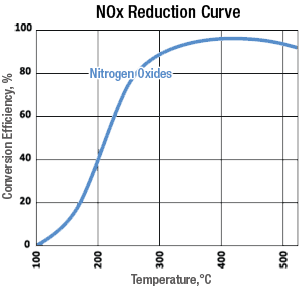

- Exhaust temperature data logging will be performed before each installation, and exhaust temperatures must be above 325 degrees °C for at least 25% of the normal duty cycle. As there may be significant variations from application to application, Nett Technologies will review actual engine operating conditions and perform temperature data-logging prior to retrofitting an engine with the BlueMAX™ PLUS 100 system to ensure compatibility.

- Each installation will be equipped with a monitoring system that displays warning lights and error codes visible to the operator, providing urea tank level and diagnostic information.

- The engine/equipment must not be equipped with a crankcase oil burning system.

- The engine should be well maintained and not consume lubricating oil at a rate greater than that specified by the engine manufacturer.

- The engine must not have been originally certified or equipped with a DOC or diesel particulate filter (DPF).

- The DPF component of the system is recommended for service every 1000 hours of use.

For more information please visit EPA website https://www.epa.gov/verified-diesel-tech/nett-technologies-inc-bluemaxtm-plus-100-selective-catalytic-reduction-scr

BlueMAX™ PLUS-Series - Technology

BlueMAX™ PLUS-Series System Schematic Drawing

BlueMAX™ PLUS-Series - Performance

BlueMAX™ PLUS-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ PLUS-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ PLUS-Series Standard Models (GT)

| Max. Engine Power | ||

| Model | hp | kW |

| GT5100 | 100 | 75 |

| GT5200 | 150 | 110 |

| GT5300 | 200 | 150 |

| GT5400 | 250 | 185 |

| GT5500 | 300 | 225 |

| GT5600 | 350 | 260 |

| GT5700 | 400 | 300 |

| GT5800 | 450 | 335 |

| GT5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ PLUS-Series Selective Catalytic Reduction (SCR) and Passive Diesel Particulate Filter (DPF) system is typically installed under-hood, retaining the equipment's factory appearance and operator sight-lines.

BlueMAX™ PLUS 100 - Verification

The BlueMAX™ PLUS 100 Selective Catalytic Reduction (SCR) system represents the industry’s only Nitrogen Oxides (NOx) and Particulate Matter (PM) retrofit emission control device to be commercially available to the non-road market. Nett Technologies’ BlueMAX™ PLUS 100 SCR system has been designed to reduce NOx and PM by a minimum of 85% from medium-and heavy-duty non-road diesel engines ranging between 75 and 560 kW (100-750 hp). In addition to removing NOx and PM, the system also has the added benefit of reducing Carbon Monoxide (CO) emissions by 95% and Hydrocarbons (HC) by 60%. This product is well suited for known PM2.5 and ozone nonattainment areas were controlling both PM and NOx are key factors towards adopting appropriate State Implementation Plans (SIPs) under the Clean Air Act.

The BlueMAX™ PLUS 100 system consists of a passive Diesel Particulate Filter (DPF) followed by a urea SCR system. “The BlueMAX™ PLUS 100 is a great retrofit emission control solution for non-road engines certified to Tier 1, 2 or 3 emission standards. The system is a durable and versatile emission control solution that extends the years of usage of existing construction and non-road equipment. Thanks largely to its direct-fit design, the system not only meets the latest regulations but is highly efficient in its operation.

Criteria to achieve emission reductions

The following criteria must be met in order for appropriately retrofitted engines to achieve the aforementioned emission reductions:

- Baseline engine must be in a certified configuration and operating on fuel with less than 15 ppm sulfur.

- Exhaust temperature data logging will be performed before each installation, and exhaust temperatures must be above 325 degrees °C for at least 25% of the normal duty cycle. As there may be significant variations from application to application, Nett Technologies will review actual engine operating conditions and perform temperature data-logging prior to retrofitting an engine with the BlueMAX™ PLUS 100 system to ensure compatibility.

- Each installation will be equipped with a monitoring system that displays warning lights and error codes visible to the operator, providing urea tank level and diagnostic information.

- The engine/equipment must not be equipped with a crankcase oil burning system.

- The engine should be well maintained and not consume lubricating oil at a rate greater than that specified by the engine manufacturer.

- The engine must not have been originally certified or equipped with a DOC or diesel particulate filter (DPF).

- The DPF component of the system is recommended for service every 1000 hours of use.

For more information please visit EPA website https://www.epa.gov/verified-diesel-tech/nett-technologies-inc-bluemaxtm-plus-100-selective-catalytic-reduction-scr

Downloadable Documents

BlueMAX™ PLUS 100 Brochure (Off-road)BlueMAX™ PLUS Fact SheetBlueMAX™ PLUS-Series Maintenance Card

Verification

Photo Gallery