Emission control solutions for LPG, CNG and gasoline engines

California ARB Verifies Nett’s GreenTRAP™ Diesel Particulate Filter

The California ARB has verified the Nett GreenTRAP™ system for its Airborne Toxic Control Measure (ATCM) for stationary compression ignition engines. The verification covers stationary prime and emergency standby generators and pumps powered by certified off-road diesel engines meeting 0.2 grams per brake horsepower hour (g/bhp-hr) PM or less. The GreenTRAP™ catalytic diesel particulate filter utilizes a wall-flow filter monolith coated with a proprietary catalyst to enable passive regeneration (self-cleaning) at typical diesel exhaust temperatures. Specific engine criteria for which the GreenTRAP™ system has been approved may be found on the Executive Order, which will be posted shortly on the California ARB website: (http://www.arb.ca.gov/diesel/verdev/vt /stationary.htm).

Diesel engines emit a complex mixture of air pollutants, composed of gaseous, liquid and solid materials. The visible emissions in diesel exhaust are known as particulate matter or PM, which include carbon particles commonly referred to as “soot”. In 1998, following a 10-year scientific assessment process, the ARB identified diesel PM as a toxic air contaminant based on its potential to cause cancer and other health problems, including respiratory illnesses and increased risk of heart disease. Health risks from diesel PM are highest in areas of concentrated emissions, such as near ports, rail yards, freeways or warehouse distribution centers.

To reduce public exposure to diesel PM, in 2000, the ARB approved the Risk Reduction Plan to Reduce Particulate Matter Emission from Diesel-Fueled Engines and Vehicles. Integral to this plan is the implementation of control measures to reduce diesel PM such as the ATCM for stationary diesel-fueled engines. Among other provisions, the ATCM established emission standards and fuel use requirements for new and in-use stationary engines used in prime and emergency back-up applications. In addition to PM, the ATCM establishes emission standards for hydrocarbons (HC), nitrogen oxides (NOx), non-methane hydrocarbons and NOx (NMHC+NOx), and carbon monoxide (CO).

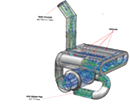

GreenTRAP™ diesel particulate filters utilize cordierite wall-flow monoliths to trap the soot produced by diesel engines. The cylindrical filter element consists of many square parallel channels separated by thin porous walls. The channels are open at one end and plugged at the other, which forces the particle laden exhaust gases to flow through the walls. Gas is able to escape through the pores in the wall material. Particulates, however, are too large to escape and are trapped in the filter walls and in the inlet channels. A proprietary catalyst is coated onto the inside surface of the filter monolith. The catalyst lowers the soot combustion temperature allowing the filter to regenerate. The accumulated soot is oxidized in the filter during regular operation of the engine. Due to the presence of the catalyst, reductions in carbon monoxide (CO) and hydrocarbon (HC) emissions are also observed and are similar to that of a standard diesel oxidation catalyst (DOC).

Information on California Air Resources Board (ARB)

California’s Legislature established the Air Resources Board (ARB) in 1967 to:

- Attain and maintain healthy air quality.

- Conduct research into the causes of and solutions to air pollution.

- Systematically attack the serious problem caused by motor vehicles, which are the major causes of air pollution in the State.

For more information, please visit the California ARB’s website at: http://www.arb.ca.gov/homepage.htm