ML-Series

Exhaust Gas And Temperature Diluters Features

- Ideal for vehicles and stationary engines operating within the range of 135 to 2400hp.

- The ML-Series diluters will greatly dilute and cool hazardous engine exhaust gases ensuring the operators are working in a safer and healthier environment.

- Reduced risk of igniting nearby flammable or combustible materials due to lower exhaust temperatures.

- For operators of vehicles within tunnels, containers and warehouses, the ML-Series diluters can be designed such that the exhaust flow is projected away from the vehicle or stationary equipment.

- Quiet operation - no mechanical or moving parts.

- The ML-Series dilutors are ruggedly built to withstand rough operating conditions for extended periods.

- The ML-Series diluters have a low initial cost, and minimum maintenance requirements resulting in a very low total life cycle cost.

- Adjustable shims to allow for optimal dilution performance.

ML-Series - Technology

The ML-Series diluters from Nett Technologies are designed to greatly dilute and cool hazardous engine exhaust gases that are emitted from vehicles and stationary equipment within the range of 135 to 2400hp. By mixing ambient air with engine exhaust gas in an approximate 5:1 to 10:1 ratio and with its slim design, the ML-Series diluters are engineered to deliver a safer and less hazardous environment. In addition to diluting your exhaust gas, the conditioned exhaust experiences a substantial reduction in temperature, which ultimately leads to a safer environment.

Narrow in design to fit into tight places, the ML-Series diluters are ideal for diesel engines applicable to the power generation and utility, construction, material handling and mining industries. Capable of being wall-mounted, these diluters reduce concentrations of hazardous exhaust gases by projecting away, spreading and diluting them over a wider and lower concentration area. If exhaust emissions reduction is also required, the ML-Series dilutors can be integrated with an emission control system.

Manufactured from high grade mild, galvanized, or stainless steel, these ruggedly built diluters have no mechanical or moving parts and can also be custom engineered to accommodate your diverse and every dilution requirement. With their quiet operation and minimum maintenance requirement, the Nett Technologies’ ML-Series diluters are an ideal solution for diluting your exhaust gases.

ML-Series - Performance

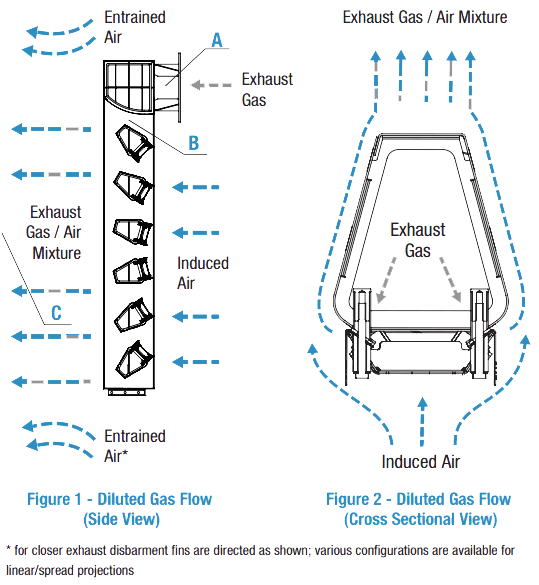

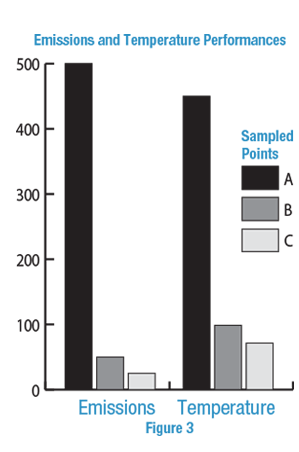

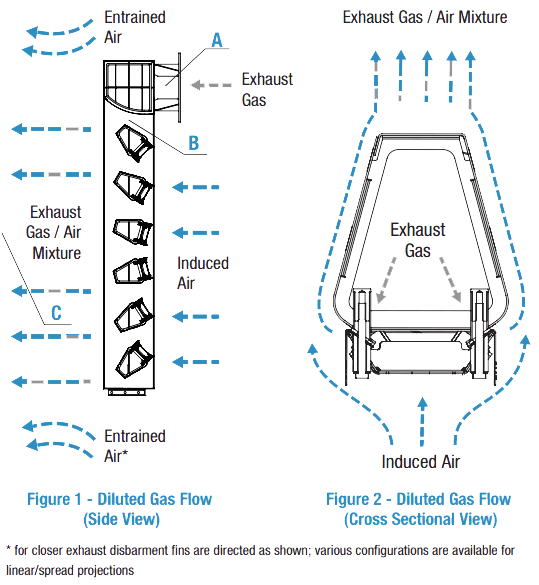

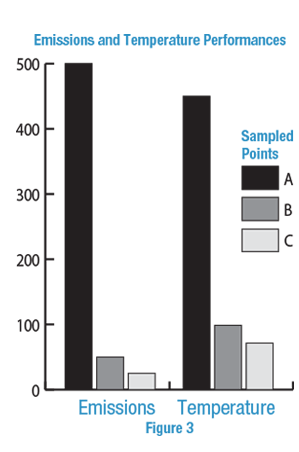

Engine exhaust gases enter the inlet, where initial air mixing occurs, and are redirected towards the channels of the diluter, as shown in Figure 1 and Figure 2. The exhaust gases flow alongside the inside surface of the channels, inducing quantities of ambient air into the diluter. The result is a diluted and cooled exhaust gas/air mixture. Figure 3 represents the exhaust emissions and temperatures sampled at three points, A, B, and C of the diluter system. As shown in Figure 1, these points represent the undiluted exhaust (A), the exhaust inside the diluter tube (B), and gasses at 1m distance after the diluter (C). The emissions are expressed in ppm. The same concentration reductions apply to all emissions, including diesel particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

Figure 3 represents the exhaust emissions and temperatures sampled at three points, A, B, and C of the diluter system. As shown in Figure 1, these points represent the undiluted exhaust (A), the exhaust inside the diluter tube (B), and gasses at 1m distance after the diluter (C). The emissions are expressed in ppm. The same concentration reductions apply to all emissions, including diesel particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). Both the emission dilutions and the exhaust cooling effect depend on the diluter gap settings. For different applications, these settings can be adjusted to always achieve the highest system performance. The corresponding exhaust gas pressure drop across the diluter is typically 5-7 kPa (20-28 in. H2O). The gap settings can be easily adjusted to change the dilutions and pressure losses by applying variable thickness shims underneath the diluter header.

Both the emission dilutions and the exhaust cooling effect depend on the diluter gap settings. For different applications, these settings can be adjusted to always achieve the highest system performance. The corresponding exhaust gas pressure drop across the diluter is typically 5-7 kPa (20-28 in. H2O). The gap settings can be easily adjusted to change the dilutions and pressure losses by applying variable thickness shims underneath the diluter header.ML-Series - Technology

The ML-Series diluters from Nett Technologies are designed to greatly dilute and cool hazardous engine exhaust gases that are emitted from vehicles and stationary equipment within the range of 135 to 2400hp. By mixing ambient air with engine exhaust gas in an approximate 5:1 to 10:1 ratio and with its slim design, the ML-Series diluters are engineered to deliver a safer and less hazardous environment. In addition to diluting your exhaust gas, the conditioned exhaust experiences a substantial reduction in temperature, which ultimately leads to a safer environment.

Narrow in design to fit into tight places, the ML-Series diluters are ideal for diesel engines applicable to the power generation and utility, construction, material handling and mining industries. Capable of being wall-mounted, these diluters reduce concentrations of hazardous exhaust gases by projecting away, spreading and diluting them over a wider and lower concentration area. If exhaust emissions reduction is also required, the ML-Series dilutors can be integrated with an emission control system.

Manufactured from high grade mild, galvanized, or stainless steel, these ruggedly built diluters have no mechanical or moving parts and can also be custom engineered to accommodate your diverse and every dilution requirement. With their quiet operation and minimum maintenance requirement, the Nett Technologies’ ML-Series diluters are an ideal solution for diluting your exhaust gases.

ML-Series - Performance

Engine exhaust gases enter the inlet, where initial air mixing occurs, and are redirected towards the channels of the diluter, as shown in Figure 1 and Figure 2. The exhaust gases flow alongside the inside surface of the channels, inducing quantities of ambient air into the diluter. The result is a diluted and cooled exhaust gas/air mixture. Figure 3 represents the exhaust emissions and temperatures sampled at three points, A, B, and C of the diluter system. As shown in Figure 1, these points represent the undiluted exhaust (A), the exhaust inside the diluter tube (B), and gasses at 1m distance after the diluter (C). The emissions are expressed in ppm. The same concentration reductions apply to all emissions, including diesel particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

Figure 3 represents the exhaust emissions and temperatures sampled at three points, A, B, and C of the diluter system. As shown in Figure 1, these points represent the undiluted exhaust (A), the exhaust inside the diluter tube (B), and gasses at 1m distance after the diluter (C). The emissions are expressed in ppm. The same concentration reductions apply to all emissions, including diesel particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). Both the emission dilutions and the exhaust cooling effect depend on the diluter gap settings. For different applications, these settings can be adjusted to always achieve the highest system performance. The corresponding exhaust gas pressure drop across the diluter is typically 5-7 kPa (20-28 in. H2O). The gap settings can be easily adjusted to change the dilutions and pressure losses by applying variable thickness shims underneath the diluter header.

Both the emission dilutions and the exhaust cooling effect depend on the diluter gap settings. For different applications, these settings can be adjusted to always achieve the highest system performance. The corresponding exhaust gas pressure drop across the diluter is typically 5-7 kPa (20-28 in. H2O). The gap settings can be easily adjusted to change the dilutions and pressure losses by applying variable thickness shims underneath the diluter header.