BlueMAX™ VOLT-Series

SCR and Active DPF System Features

- The system consists of an Active Diesel Particulate Filter (ADPF) (electrically regenerated) and urea-based Selective Catalytic Reduction (SCR) systems

- BlueMAX™ VOLT 100 is ideal for Off-road application (construction, mining, material handling), BlueMAX™ VOLT 200 – On-road, BlueMAX™ VOLT 300 – Power Generation, BlueMAX™ VOLT 320 – Marine, BlueMAX™ VOLT 350 – Gantry Cranes, BlueMAX™ VOLT 420 – Locomotive industry

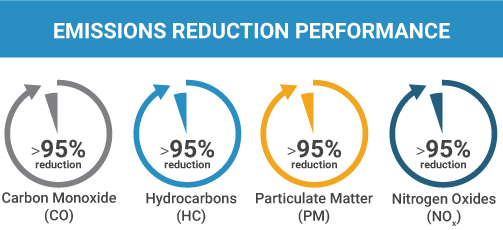

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC), Nitrogen Oxides (NOx) and Particulate Matter (PM) emissions from your diesel engine

- Internally and externally (optional) insulated

- Computerized controller with 3 customizable alarms

- Maintenance intervals of 2000 to 6000 hours

- Programmable regeneration profile with data logging capabilities

- Colour display informing of system operating conditions and status

- Continuous generator load monitoring for optimum regeneration strategy

- Energy efficient with quiet operation

BlueMAX™ VOLT-Series - Technology

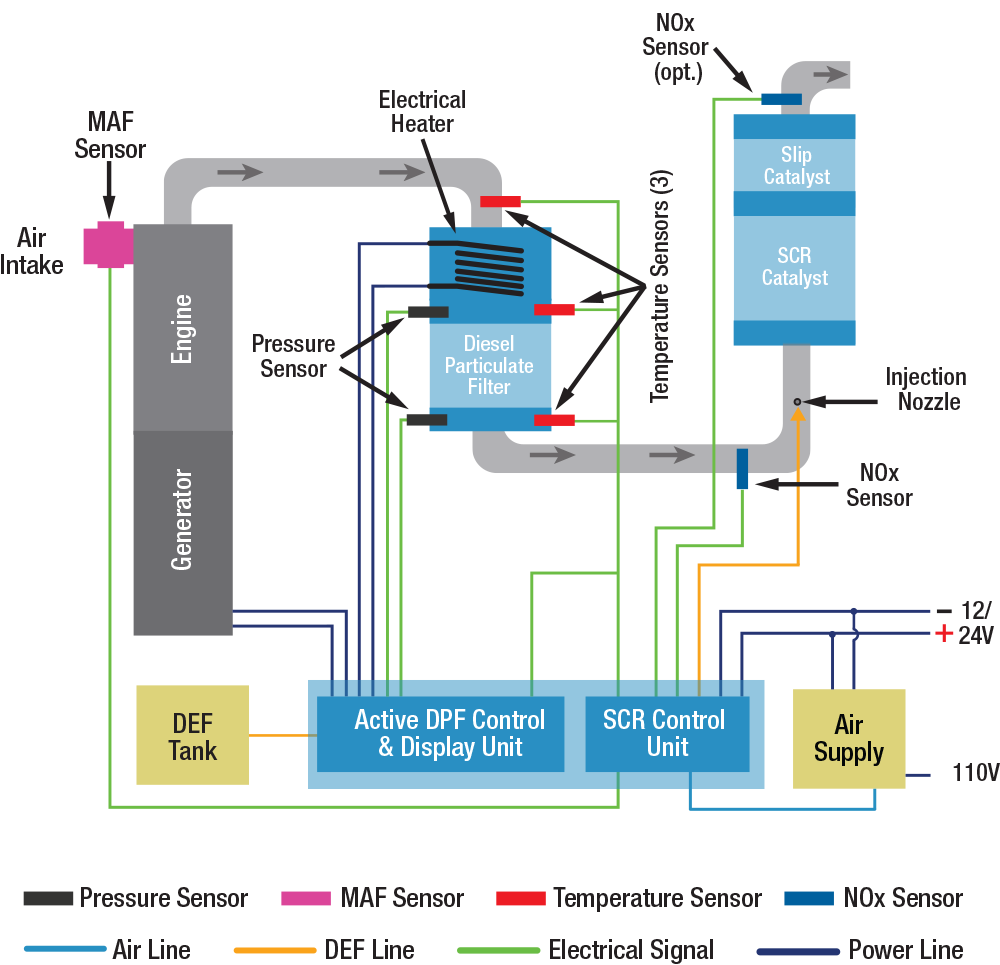

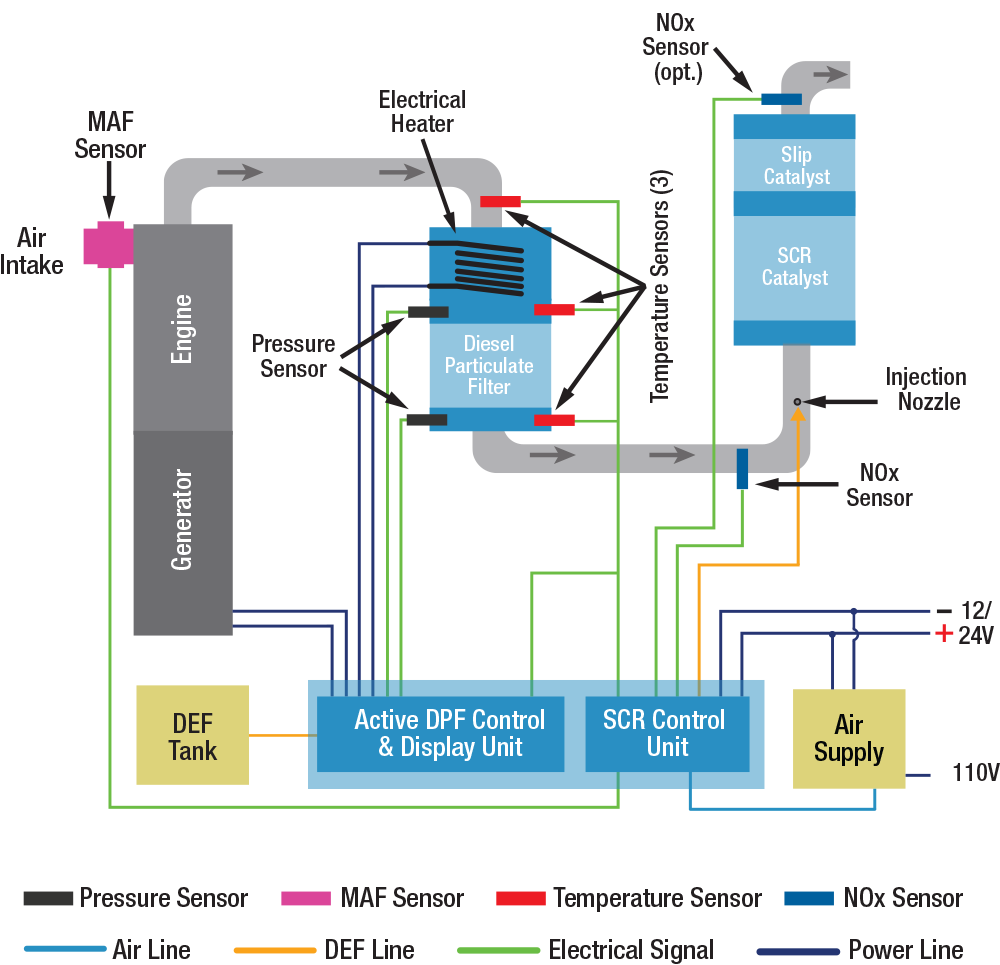

The BlueMAX™ VOLT-Series is an emission control system consisting of a Diesel Particulate Filter (DPF) upstream of a Selective Catalytic Reduction (SCR). It is designed to control emissions of both Particulate Matter (PM) and Nitrogen Oxides (NOx) from medium and heavy-duty diesel engines in stationary applications. The system uses a proprietary catalyst on the inner surfaces of the DPF walls which reduces the regeneration temperature and therefore allows the system to passively regenerate in favorable engine exhaust operating temperatures. When a temperature is not sufficient for passive regeneration, a set of electric heater coils are used to increase the exhaust temperature for active regeneration. An Electronic Control Unit (ECU) evaluates the system parameters such as temperature, pressure and exhaust mass flow rate in real time and uses these values to predict and activate the regeneration cycle.

In the Nett BlueMAX™ VOLT-Series, NOx is reduced over the SCR catalyst through a chemical reaction with Diesel Exhaust Fluid (DEF). The SCR sub-system consists of the SCR catalytic converter, a DEF dosing unit, and the DEF tank (see diagram). The DEF control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine mass air flow sensor and temperature sensors, the ECU calculates the amount of urea which needs to be injected for optimum NOx reductions. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

The Nett BlueMAX™ VOLT-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display. The system provides up to 95% emissions reduction in Particulate Matter (PM), Oxides of Nitrogen (NOx), Carbon Monoxide (CO) and Hydrocarbons (HC).

BlueMAX™ VOLT-Series - Performance

Nett Technologies’ BlueMAX™ VOLT-Series is an Active Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system which is designed to control emissions of Particulate Matter (PM) and Oxides of Nitrogen (NOx) from medium and heavy-duty diesel engines in stationary applications. The system contains a set of electric heater coils that are used to increase the temperature of the exhaust for active regeneration allowing the system to run without relying on engine exhaust temperatures. The wall-flow DPF traps PM/soot emissions emitted by the diesel engines. The cylindrical filter element of the device consists of many square parallel channels running in the axial direction, separated by thin porous walls. A proprietary catalyst is wash-coated on the inner surfaces of the monolith channels. The inner catalyst lowers the PM oxidation temperature allowing a filter to passively regenerate at lower temperatures. When the exhaust temperature is not sufficient for passive regeneration, an active regeneration will be automatically triggered. During active regeneration, the electrical control unit utilizes excessive power of your generator in a controlled manner to increase the exhaust temperature to levels that can safely oxidize collected soot in the DPF. NOx is reduced over the SCR catalyst through a chemical reaction with a reducing agent 'urea' commonly referred to as Diesel Exhaust Fluid (DEF). The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal, in combination with an engine mass air flow sensor and temperature sensors, the Electronic Control Unit (ECU) calculates the amount of urea which needs to be injected for optimum NOx reductions.BlueMAX™ VOLT-Series System Schematic Drawing

BlueMAX™ VOLT-Series - Designs and Options

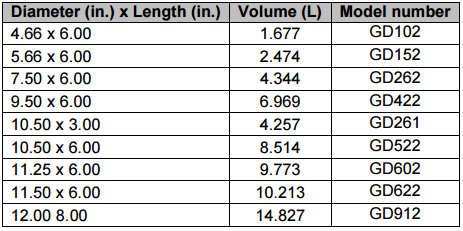

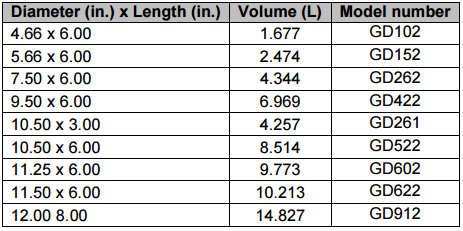

Standard models and sizing charts for the Nett BlueMAX™ VOLT-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ VOLT-Series Standard Models (GD)

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ VOLT-Series system is typically installed under-hood, retaining the equipment's factory appearance and operator sightlines.

BlueMAX™ VOLT-Series - Technology

The BlueMAX™ VOLT-Series is an emission control system consisting of a Diesel Particulate Filter (DPF) upstream of a Selective Catalytic Reduction (SCR). It is designed to control emissions of both Particulate Matter (PM) and Nitrogen Oxides (NOx) from medium and heavy-duty diesel engines in stationary applications. The system uses a proprietary catalyst on the inner surfaces of the DPF walls which reduces the regeneration temperature and therefore allows the system to passively regenerate in favorable engine exhaust operating temperatures. When a temperature is not sufficient for passive regeneration, a set of electric heater coils are used to increase the exhaust temperature for active regeneration. An Electronic Control Unit (ECU) evaluates the system parameters such as temperature, pressure and exhaust mass flow rate in real time and uses these values to predict and activate the regeneration cycle.

In the Nett BlueMAX™ VOLT-Series, NOx is reduced over the SCR catalyst through a chemical reaction with Diesel Exhaust Fluid (DEF). The SCR sub-system consists of the SCR catalytic converter, a DEF dosing unit, and the DEF tank (see diagram). The DEF control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine mass air flow sensor and temperature sensors, the ECU calculates the amount of urea which needs to be injected for optimum NOx reductions. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

The Nett BlueMAX™ VOLT-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display. The system provides up to 95% emissions reduction in Particulate Matter (PM), Oxides of Nitrogen (NOx), Carbon Monoxide (CO) and Hydrocarbons (HC).

BlueMAX™ VOLT-Series - Performance

Nett Technologies’ BlueMAX™ VOLT-Series is an Active Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system which is designed to control emissions of Particulate Matter (PM) and Oxides of Nitrogen (NOx) from medium and heavy-duty diesel engines in stationary applications. The system contains a set of electric heater coils that are used to increase the temperature of the exhaust for active regeneration allowing the system to run without relying on engine exhaust temperatures. The wall-flow DPF traps PM/soot emissions emitted by the diesel engines. The cylindrical filter element of the device consists of many square parallel channels running in the axial direction, separated by thin porous walls. A proprietary catalyst is wash-coated on the inner surfaces of the monolith channels. The inner catalyst lowers the PM oxidation temperature allowing a filter to passively regenerate at lower temperatures. When the exhaust temperature is not sufficient for passive regeneration, an active regeneration will be automatically triggered. During active regeneration, the electrical control unit utilizes excessive power of your generator in a controlled manner to increase the exhaust temperature to levels that can safely oxidize collected soot in the DPF. NOx is reduced over the SCR catalyst through a chemical reaction with a reducing agent 'urea' commonly referred to as Diesel Exhaust Fluid (DEF). The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal, in combination with an engine mass air flow sensor and temperature sensors, the Electronic Control Unit (ECU) calculates the amount of urea which needs to be injected for optimum NOx reductions.BlueMAX™ VOLT-Series System Schematic Drawing

BlueMAX™ VOLT-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ VOLT-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ VOLT-Series Standard Models (GD)

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ VOLT-Series system is typically installed under-hood, retaining the equipment's factory appearance and operator sightlines.

Downloadable Documents

Photo Gallery