Generator Silencers Features

- Over 25 years of excellence in manufacturing noise and emission control solutions

- Compact modular designs providing ease of installations, less weight, and less footprint

- Responsive lead time for both standard and custom designs to meet your needs

- Customized engineered systems solutions to meet challenging integration and engine requirements

- Versatile connections including ANSI pattern flanges, NPT, slip-on, engine flange, schedule 40 and others

- Aluminized Steel, Mild Steel, Stainless Steel 304 or 316 construction

- Horizontal or vertical mounting brackets and lifting lugs

- Wide range of silencer accessories, we are your one-stop shop solution for all silencer needs

By supplying myriads of cost-effective compact and low pressure drop silencers, Nett Technologies Inc is leading the way through innovations, technologies, design engineering, optimizations, customer service and lead-time in engine exhaust silencer. Primarily for the industrial and power generation market including but not limited to Caterpillar, Cummins, John Deere, Perkins and Doosan Engines.

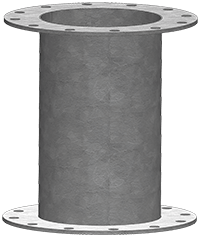

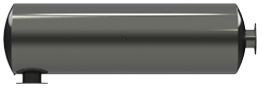

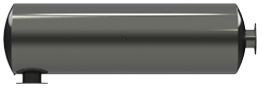

CYLINDRICAL SILENCERS SPEC SHEETS

Industrial Grade, 15-20dBA (NTIN-C)

Residential Grade, 20-25dBA (NTRS-C)

Residential Plus Grade, 23-28dBA (NTRP-C)

Critical Grade, 25-30dBA (NTCR-C)

Critical Plus Grade, 28-33dBA (NTCP-C)

Super Critical Grade, 30-35dBA (NTSC-C)

Super Critical Plus Grade, 33-38dBA (NTSP-C)

Hospital Grade, 35-40dBA (NTHO-C)

The silencer inlet/outlet diameters, as well as their locations, can be customized to the application. Virtually all other dimensions, material and paint color can be customized upon request.

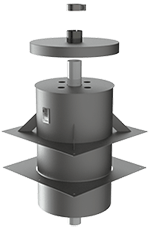

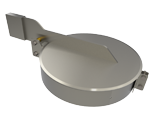

DISC (HOCKEY PUCK) SILENCERS SPEC SHEETS

Residential, 20-25dBA (NTRS-D)

Residential (1" ins), 22-27dBA (NTRS1-D)

Residential (2" ins), 24-29bBA (NTRS2-D)

Critical (1" ins), 27-32dBA (NTCR1-D)

Critical (2" ins), 29-34dBA (NTCR2-D)

Super Critical, 30-37dBA (NTSC-D)

Super Critical (1" ins), 32-39dBA (NTSC1-D)

Super Critical (2" ins), 34-41dBA (NTSC2-D)

Hospital (1" ins), 35-40dBA (NTHO1-D)

The silencer inlet/outlet diameters, as well as their locations, can be customized to the application. Virtually all other dimensions, material and paint color can be customized upon request.

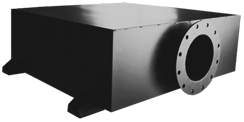

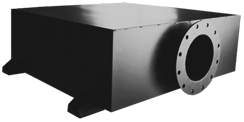

RECTANGULAR SILENCERS SPEC SHEETS

Residential, 20-25dBA (NTRS-R)

Residential (1" ins), 22-27dBA (NTRS1-R)

Residential (2" ins), 24-29bBA (NTRS2-R)

Critical (1" ins), 27-32dBA (NTCR1-R)

Critical (2" ins), 29-34dBA (NTCR2-R)

Super Critical, 30-37dBA (NTSC-R)

Super Critical (1" ins), 32-39dBA (NTSC1-R)

Super Critical (2" ins), 34-41dBA (NTSC2-R)

Hospital (1" ins), 37-44dBA (NTHO1-R)

Hospital (2" ins), 39-46dBA (NTHO2-R)

Hospital Plus (1" ins), 40-50dBA (NTHP1-R)

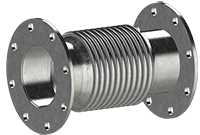

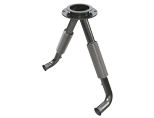

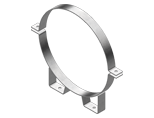

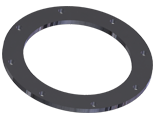

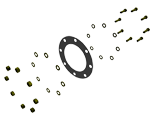

Nett Technologies offers the following silencer accessories:

|

Clamps (coming soon)

|

||

CYLINDRICAL SILENCERS SPEC SHEETS

Industrial Grade, 15-20dBA (NTIN-C)

Residential Grade, 20-25dBA (NTRS-C)

Residential Plus Grade, 23-28dBA (NTRP-C)

Critical Grade, 25-30dBA (NTCR-C)

Critical Plus Grade, 28-33dBA (NTCP-C)

Super Critical Grade, 30-35dBA (NTSC-C)

Super Critical Plus Grade, 33-38dBA (NTSP-C)

Hospital Grade, 35-40dBA (NTHO-C)

The silencer inlet/outlet diameters, as well as their locations, can be customized to the application. Virtually all other dimensions, material and paint color can be customized upon request.

DISC (HOCKEY PUCK) SILENCERS SPEC SHEETS

Residential, 20-25dBA (NTRS-D)

Residential (1" ins), 22-27dBA (NTRS1-D)

Residential (2" ins), 24-29bBA (NTRS2-D)

Critical (1" ins), 27-32dBA (NTCR1-D)

Critical (2" ins), 29-34dBA (NTCR2-D)

Super Critical, 30-37dBA (NTSC-D)

Super Critical (1" ins), 32-39dBA (NTSC1-D)

Super Critical (2" ins), 34-41dBA (NTSC2-D)

Hospital (1" ins), 35-40dBA (NTHO1-D)

The silencer inlet/outlet diameters, as well as their locations, can be customized to the application. Virtually all other dimensions, material and paint color can be customized upon request.

RECTANGULAR SILENCERS SPEC SHEETS

Residential, 20-25dBA (NTRS-R)

Residential (1" ins), 22-27dBA (NTRS1-R)

Residential (2" ins), 24-29bBA (NTRS2-R)

Critical (1" ins), 27-32dBA (NTCR1-R)

Critical (2" ins), 29-34dBA (NTCR2-R)

Super Critical, 30-37dBA (NTSC-R)

Super Critical (1" ins), 32-39dBA (NTSC1-R)

Super Critical (2" ins), 34-41dBA (NTSC2-R)

Hospital (1" ins), 37-44dBA (NTHO1-R)

Hospital (2" ins), 39-46dBA (NTHO2-R)

Hospital Plus (1" ins), 40-50dBA (NTHP1-R)

Nett Technologies offers the following silencer accessories:

|

Clamps (coming soon)

|

||

Downloadable Documents

Photo Gallery