BlueMAX™ NOVA-Series

SCR, Active DPF and DOC System Features

- Nett Technologies’ BlueMAX™ NOVA-Series is an Active DPF, DOC and SCR system which is designed to control emissions of Particulate Matter (PM) and Oxides of Nitrogen (NOx), Carbon Monoxide (CO) and Hydrocarbons (HC) from medium and heavy-duty diesel engines

- BlueMAX™ NOVA 100 is ideal for Off-road application (construction, mining, material handling), BlueMAX™ NOVA 200 – On-road, BlueMAX™ NOVA 300 – Power Generation, BlueMAX™ NOVA 320 – Marine, BlueMAX™ NOVA 350 – Gantry Cranes, BlueMAX™ NOVA 420 – Locomotive industry

- BlueMAX NOVA 300e (stationary) is verified by California Air Resources Board (CARB) for diesel engines certified to Tier 1, Tier 2 and Tier 3 with a rating equal to or greater than 75 hp/56 kW

- Level 3 Plus, Mark 5 Verification (PM & NOx at least 85% reduction)

- Internally insulated with optional external insulation available

- Computerized controller with 3 customizable alarms

- Maintenance intervals of 2000 to 6000 hours

- Data logging capabilities

- Colour display informing of system operating conditions and status

- Energy efficient with quiet operation

BlueMAX™ NOVA-Series - Technology

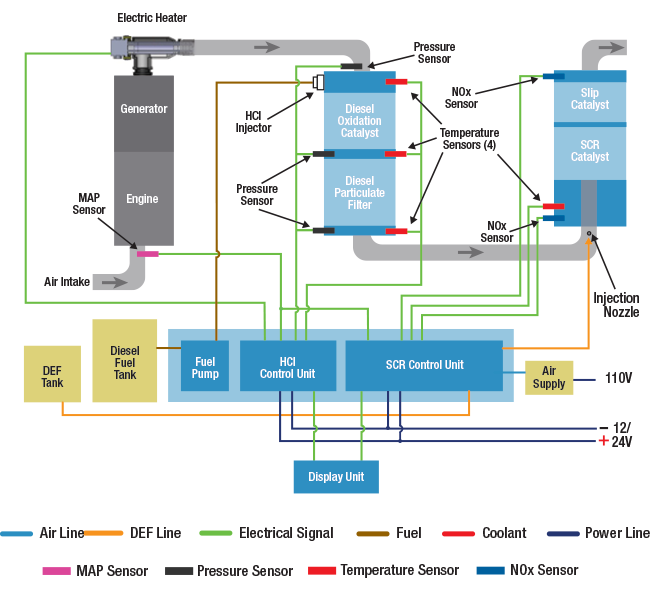

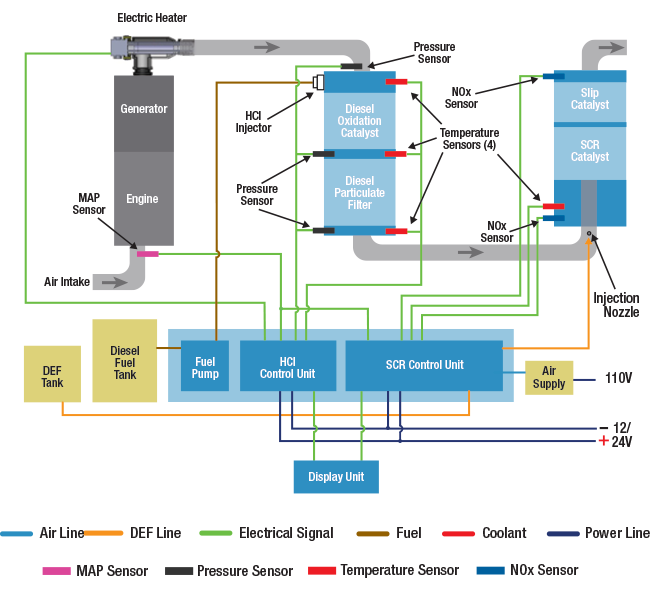

The main components of the BlueMAX™ NOVA-Series system include the Selective Catalytic Reduction (SCR) catalytic converter, the computerized Urea Dosing System (UDS), the urea tank (see diagram), the Diesel Particulate Filter (DPF), the Diesel Oxidation Catalyst (DOC) and HCI control components. The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine air mass flow sensor and temperature sensors, the computer calculates the amount of urea which needs to be injected for optimum NOx reductions.

The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

BlueMAX™ NOVA-Series - Performance

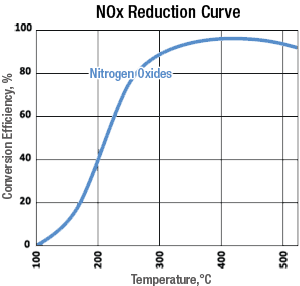

Urea (in the form of a 32.5% water-based solution) is metered by a computer controlled dosing pump into the exhaust pipe upstream of the Selective Catalytic Reduction (SCR) catalyst through an injection nozzle. Compressed air from the air brake line or a standalone air compressor is used to atomize the urea for optimum dispersion, to maximize the NOx reductions and minimize the amount of urea required. The injected urea solution evaporates in the hot exhaust gas and decomposes producing ammonia. Through catalytic reactions with ammonia, NOx emissions are reduced to harmless products including nitrogen and water vapor.

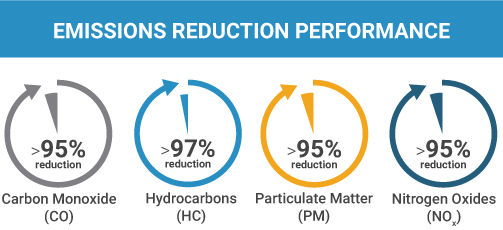

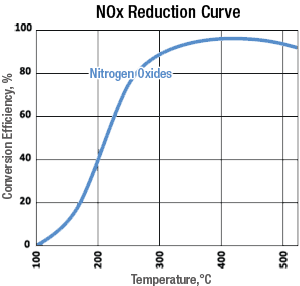

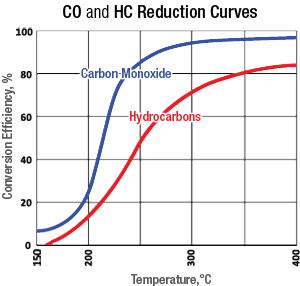

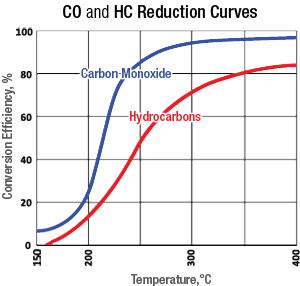

The BlueMAX™ NOVA-Series system includes an ammonia slip catalyst (oxidation catalyst) as a standard feature. The ammonia slip catalyst prevents the possibility that unreacted ammonia is released from the vehicle tailpipe. The catalyst consists of a metallic monolith honeycomb substrate coated with platinum group metal catalyst. The honeycomb structure with many small parallel channels presents a high catalytic contact area for the exhaust gases. Due to the presence of an oxidation catalyst reductions in Carbon Monoxide (CO) and Hydrocarbon (HC) emissions are achieved in addition to ammonia slip control. Typical conversion efficiencies NOx as well as for CO and HC are illustrated in the graphs below.

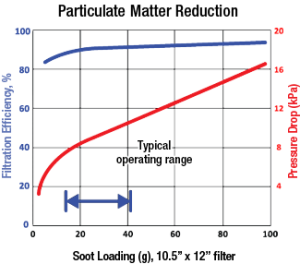

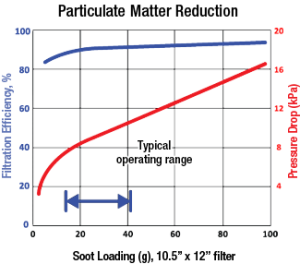

Additionally, the BlueMAX™ NOVA-Series includes an Active Diesel Particulate Filter (DPF) for Diesel Particulate Matter (PM) control. The soot filtration efficiency of the filter increases with the soot loading in the unit. Even at low soot loads, the filter efficiency exceeds 90% (blue line in Figure below). The visible smoke is completely eliminated by the filter, resulting in a dramatic improvement of smoke opacity readings.

BlueMAX™ NOVA-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ NOVA-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ NOVA-Series Standard Models (GH)

| Max. Engine Power | ||

| Model | hp | kW |

| GH5100 | 100 | 75 |

| GH5200 | 150 | 110 |

| GH5300 | 200 | 150 |

| GH5400 | 250 | 185 |

| GH5500 | 300 | 225 |

| GH5600 | 350 | 260 |

| GH5700 | 400 | 300 |

| GH5800 | 450 | 335 |

| GH5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ NOVA-Series system is typically installed under-hood, retaining the equipment's factory appearance and operator sightlines.

BlueMAX™ NOVA 300e - Verification

The BlueMAX™ NOVA 300e is verified by California Air Resources Board (CARB) for diesel engines certified to Tier 1, Tier 2 and Tier 3 with a rating equal to or greater than 75 hp/56 kW. Diesel engine has to meet 0.2 grams per brake horsepower hour (g/bhp-hr) diesel Particulate Matter (PM) or less based on certification or in-use emissions testing (as tested on an appropriate steady-state certification cycle outlined in the ARB off-road regulations – similar to ISO 8178 D2). Also, the BlueMAX™ NOVA 300e is verified for diesel engines Tier 4i with a rated power over 750 hp/560 kW, or Tier 4 Alt 20% NOx and PM, emitting PM at a rate of 0.2 g/bhp-hr or less. . The achieved reduction levels make this system the product with the highest emissions reduction levels verified for the retrofit market. It is an ideal product for prime power and peak power shaving generators.

For more information about the BlueMAX™ NOVA 300e ARB verification, please visit official ARB website http://www.arb.ca.gov/diesel/verdev/vt/stationary/netttech/eode061814.pdf

BlueMAX™ NOVA-Series - Technology

The main components of the BlueMAX™ NOVA-Series system include the Selective Catalytic Reduction (SCR) catalytic converter, the computerized Urea Dosing System (UDS), the urea tank (see diagram), the Diesel Particulate Filter (DPF), the Diesel Oxidation Catalyst (DOC) and HCI control components. The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine air mass flow sensor and temperature sensors, the computer calculates the amount of urea which needs to be injected for optimum NOx reductions.

The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

BlueMAX™ NOVA-Series - Performance

Urea (in the form of a 32.5% water-based solution) is metered by a computer controlled dosing pump into the exhaust pipe upstream of the Selective Catalytic Reduction (SCR) catalyst through an injection nozzle. Compressed air from the air brake line or a standalone air compressor is used to atomize the urea for optimum dispersion, to maximize the NOx reductions and minimize the amount of urea required. The injected urea solution evaporates in the hot exhaust gas and decomposes producing ammonia. Through catalytic reactions with ammonia, NOx emissions are reduced to harmless products including nitrogen and water vapor.

The BlueMAX™ NOVA-Series system includes an ammonia slip catalyst (oxidation catalyst) as a standard feature. The ammonia slip catalyst prevents the possibility that unreacted ammonia is released from the vehicle tailpipe. The catalyst consists of a metallic monolith honeycomb substrate coated with platinum group metal catalyst. The honeycomb structure with many small parallel channels presents a high catalytic contact area for the exhaust gases. Due to the presence of an oxidation catalyst reductions in Carbon Monoxide (CO) and Hydrocarbon (HC) emissions are achieved in addition to ammonia slip control. Typical conversion efficiencies NOx as well as for CO and HC are illustrated in the graphs below.

Additionally, the BlueMAX™ NOVA-Series includes an Active Diesel Particulate Filter (DPF) for Diesel Particulate Matter (PM) control. The soot filtration efficiency of the filter increases with the soot loading in the unit. Even at low soot loads, the filter efficiency exceeds 90% (blue line in Figure below). The visible smoke is completely eliminated by the filter, resulting in a dramatic improvement of smoke opacity readings.

BlueMAX™ NOVA-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ NOVA-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ NOVA-Series Standard Models (GH)

| Max. Engine Power | ||

| Model | hp | kW |

| GH5100 | 100 | 75 |

| GH5200 | 150 | 110 |

| GH5300 | 200 | 150 |

| GH5400 | 250 | 185 |

| GH5500 | 300 | 225 |

| GH5600 | 350 | 260 |

| GH5700 | 400 | 300 |

| GH5800 | 450 | 335 |

| GH5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ NOVA-Series system is typically installed under-hood, retaining the equipment's factory appearance and operator sightlines.

BlueMAX™ NOVA 300e - Verification

The BlueMAX™ NOVA 300e is verified by California Air Resources Board (CARB) for diesel engines certified to Tier 1, Tier 2 and Tier 3 with a rating equal to or greater than 75 hp/56 kW. Diesel engine has to meet 0.2 grams per brake horsepower hour (g/bhp-hr) diesel Particulate Matter (PM) or less based on certification or in-use emissions testing (as tested on an appropriate steady-state certification cycle outlined in the ARB off-road regulations – similar to ISO 8178 D2). Also, the BlueMAX™ NOVA 300e is verified for diesel engines Tier 4i with a rated power over 750 hp/560 kW, or Tier 4 Alt 20% NOx and PM, emitting PM at a rate of 0.2 g/bhp-hr or less. . The achieved reduction levels make this system the product with the highest emissions reduction levels verified for the retrofit market. It is an ideal product for prime power and peak power shaving generators.

For more information about the BlueMAX™ NOVA 300e ARB verification, please visit official ARB website http://www.arb.ca.gov/diesel/verdev/vt/stationary/netttech/eode061814.pdf

Downloadable Documents

BlueMAX™ NOVA 300e Brochure (Stationary)

Verification

BlueMAX™ NOVA 300e Executive Order