FX-Series™

Flame Arrestors (Flame Traps) Features

Ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others.

Ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others.- Bidirectional robust design with custom versatile connections provides ease of installation.

- Maximum flow flame trap element effectively absorbs the flame without clogging the system or increasing the backpressure.

- The compact, light-weight single-element design allows easy cleaning and less maintenance resulting in cost savings.

- Available in combination with exhaust silencers and emission control solutions (DOC, DPF, SCR systems) in engine applications.

FX-Series™ - Technology

Nett Technologies’ FX-Series™ Flame Arrestors (or Flame Traps) are a low backpressure exhaust cooling solution for all of your off-road diesel engines. Designed to allow exhaust gases to pass through the arrestor, they prevent the creation of a flame which could result in a significant fire or explosion in your diesel engine application.

FX-Series™ Flame Arrestors are a cost-effective safety solution that stops the formation of a flame by removing and dissipating heat as it attempts to travel through the hundreds of narrow channels of the heat-conductive substrate. A major benefit of Nett Technologies’ Flame Arrestors is that they increase safety without causing excessive exhaust backpressure to your engine.

Nett® FX-Series™ Flame Arrestors are manufactured as passive devices with no moving parts, making them durable and long-lasting in harsh exhaust environments. These Flame Arrestors are packaged in a compact housing with diverse connection types and sizes making it easy to fit them into all of your existing exhaust tubing.

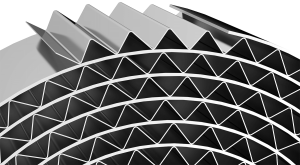

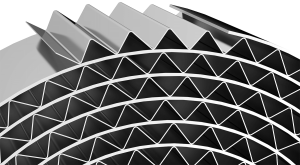

Nett® FX-Series™ Flame Arrestors are made of a crimped wound metal ribbon element as shown in the picture below.

Nett® FX-Series™ Flame Arrestor Element

Nett Technologies’ Flame Arrestors are an excellent way to control and prevent the flame transition for your off-road diesel engines.

FX-Series™ - Performance

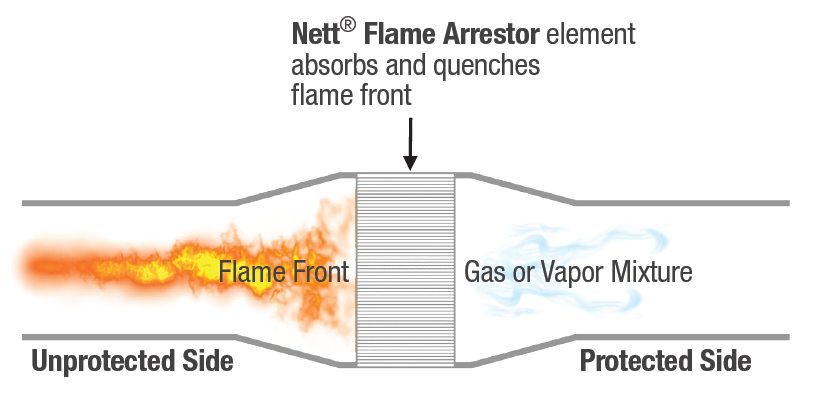

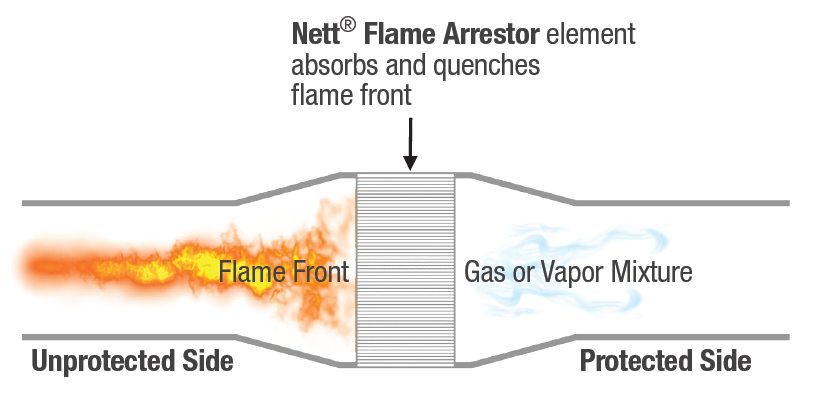

The Flame Arrestors prevent the spread of flame through the use of substrate multi-channel cell elements. This construction produces a medium with uniform channels that are carefully constructed to quench the flame by different means such as absorbing the heat of the flame and uniformly spreading it across a larger cross-section. Under normal engine operating conditions the Flame Arrestor permits a free flow of gas through the piping system.

Flame Arrestor Working Principle

Product Specifications:

Sizes: 1/2” (13mm) through 8” (200mm) nominal pipe, tube sizes.

Housing: Aluminized Steel, Carbon Steel, SS 304, SS 316.

Connectors: Flanged (ANSI, DIN, JIS), Welded.

FX-Series™ Flame Arrestors are an ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others. Virtually maintenance-free, Nett Technologies’ Flame Arrestors prevent costly equipment shutdowns and enable maximum engine uptime.

Failure to stop a flame or explosion can result in heavy damage to equipment, loss of production, injury to people and even loss of life. Flame Arrestors can prevent these catastrophic events by absorbing the flame. Contact your sales representative today to learn more about all the benefits of Nett® Flame Arrestors.

FX-Series™ - Technology

Nett Technologies’ FX-Series™ Flame Arrestors (or Flame Traps) are a low backpressure exhaust cooling solution for all of your off-road diesel engines. Designed to allow exhaust gases to pass through the arrestor, they prevent the creation of a flame which could result in a significant fire or explosion in your diesel engine application.

FX-Series™ Flame Arrestors are a cost-effective safety solution that stops the formation of a flame by removing and dissipating heat as it attempts to travel through the hundreds of narrow channels of the heat-conductive substrate. A major benefit of Nett Technologies’ Flame Arrestors is that they increase safety without causing excessive exhaust backpressure to your engine.

Nett® FX-Series™ Flame Arrestors are manufactured as passive devices with no moving parts, making them durable and long-lasting in harsh exhaust environments. These Flame Arrestors are packaged in a compact housing with diverse connection types and sizes making it easy to fit them into all of your existing exhaust tubing.

Nett® FX-Series™ Flame Arrestors are made of a crimped wound metal ribbon element as shown in the picture below.

Nett® FX-Series™ Flame Arrestor Element

Nett Technologies’ Flame Arrestors are an excellent way to control and prevent the flame transition for your off-road diesel engines.

FX-Series™ - Performance

The Flame Arrestors prevent the spread of flame through the use of substrate multi-channel cell elements. This construction produces a medium with uniform channels that are carefully constructed to quench the flame by different means such as absorbing the heat of the flame and uniformly spreading it across a larger cross-section. Under normal engine operating conditions the Flame Arrestor permits a free flow of gas through the piping system.

Flame Arrestor Working Principle

Product Specifications:

Sizes: 1/2” (13mm) through 8” (200mm) nominal pipe, tube sizes.

Housing: Aluminized Steel, Carbon Steel, SS 304, SS 316.

Connectors: Flanged (ANSI, DIN, JIS), Welded.

FX-Series™ Flame Arrestors are an ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others. Virtually maintenance-free, Nett Technologies’ Flame Arrestors prevent costly equipment shutdowns and enable maximum engine uptime.

Failure to stop a flame or explosion can result in heavy damage to equipment, loss of production, injury to people and even loss of life. Flame Arrestors can prevent these catastrophic events by absorbing the flame. Contact your sales representative today to learn more about all the benefits of Nett® Flame Arrestors.

Ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others.

Ideal safety solution for off-road diesel engine applications, such as mining, construction, power generation and others.