Emission control solutions for LPG, CNG and gasoline engines

MSHA Recognition for Nett Particulate Filters

MISSISSAUGA, ON — July 25, 2001 — Nett Technologies Inc. announces the authoritative recognition by the U.S. Mine Safety and Health Administration (MSHA) for its diesel particulate filter (DPF) technology. This technology is pivotal in assisting retrofit compliance with the newly adopted MSHA rules regarding diesel particulate matter (DPM) emissions in underground mines. It is the first legislation to control miners’ exposure to diesel particulates in U.S. mines.The coal mine rule prohibits heavy duty diesel equipment to emit levels exceeding 2.5 grams per hour of DPM with a phase-in schedule beginning May 21, 2001. The metal/non-metal (i.e. non-coal) mine rule establishes stringent DPM exposure limits effective July 19, 2001. Thousands of diesel engines in underground mines will be retrofitted with diesel particulate filters to comply with these regulations.

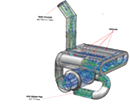

Two Nett® particulate filter technologies; cordierite, which performs in most heavy-duty applications with high exhaust temperature, accommodating engines from 15 to 450 kW in a single exhaust configuration; SiC (silicon carbide) has higher maximum operating temperature limits, accommodating engines from 13 to 206 kW in a single exhaust configuration, comply with the new MSHA diesel regulations for coal and metal/non-metal underground mines. Nett® particulate filters have been designed for heavy-duty mining equipment such as LHD loaders and haul trucks, which are the largest contributors to the total diesel particulate emissions in underground mines. The MSHA accepted filtration efficiency of Nett® filters for reducing these emissions is 85% and 87% for the cordierite and SiC technology, respectively.

The emission of DPM, commonly known as soot, is the current air quality concern in underground mining. Due to their sub-micron particle size, diesel particulates penetrate deep into human lungs contributing to numerous respiratory problems. Carcinogenic activity is also attributed to diesel particulates.

The use of diesel particulate filters is the only solution open to mine operators to meet these stringent regulations. Nett® particulate filters utilize ceramic wall-flow monoliths to trap DPM and offer unsurpassed filtration efficiency, typically in excess of 90%. The surface of the filter is coated with a proprietary catalyst, which has the ability to lower the soot combustion temperature. In contact with the catalyst, the collected diesel particulates burn out at temperatures found in the exhaust gases during regular operation of the vehicle. Thus, a self-regeneration of the filter is facilitated. Nett® filters work virtually maintenance-free on most heavy-duty diesel engines in underground mine applications.

Nett Technologies Inc. specializes in emission control products for engines, vehicles, and machinery used in the material handling, construction, and mining industries. A wide range of products available from Nett includes catalytic converters for diesel, natural gas, LPG, and gasoline engines, diesel particulate filters, and fume diluters.

Nett’s particulate filter and other technologies complying with the regulations are listed on the MSHA website at http://www.msha.gov/01-995/Coal/DPM-FilterEfflist.pdf.