Emission control solutions for LPG, CNG and gasoline engines

Nett S-Series Filters Listed by MSHA for Installation in Coal Mine Applications

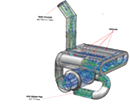

Nett Technologies Inc.’s SN and SO-Series diesel particulate filters have been listed by the Mine Safety and Health Administration (MSHA) for installation in coal mine applications. The listing is an expansion of currently listed S-Series filters for use in metal non-metal mines. SN and SO-Series filters contain an NO2 suppressant which allow these specially-catalyzed filters to be used in coal mines, and are one of only a few passive technologies listed.The SN and SO-Series filters have been tested by MSHA laboratory testing facility and listed for installation on diesel-powered mining equipment, reducing diesel particulate emissions by 85 and 87% respectively. SN-Series filters utilize a Cordierite (ceramic) filter monolith to trap diesel particulate emissions. SO-Series filters, on the other hand, use Silicon Carbide monoliths for enhanced high-temperature durability. Both series are available in a range of sizes to fit applications from 20 to over 700 hp.

Emissions of diesel particulate matter (DPM), commonly known as soot, is the biggest air quality concern in underground mining. Diesel particulates, due to their sub-micron particle size, penetrate deep into human lungs contributing to numerous respiratory problems. Carcinogenic activity is also attributed to diesel particulates. In fact, DPM has been classified as either human carcinogen or probable human carcinogen by several government agencies. MSHA published final rules in the Federal Register on January 19, 2001. These rules deal with diesel particulate matter exposure for underground miners in both coal and metal/nonmetal mines.

The use of diesel particulate filters is the only solution open to mine operators to meet the proposed regulations. Nett® particulate filters utilize ceramic wall-flow monoliths to trap DPM and offer unsurpassed filtration efficiency in excess of 85%. The surface of the filter is coated with a proprietary catalyst, which has the ability to lower the soot combustion temperature. In contact with the catalyst, the collected diesel particulates burn out at temperatures found in the exhaust gases during regular operation of the vehicle. Thus, a self-regeneration of the filter is facilitated. Nett® filters work virtually maintenance-free on most heavy-duty diesel engines in underground mine applications.

Information on the Mine Safety and Health Administration (MSHA)

MSHA is an Agency of the U.S. Department of Labor

MSHA’s Mission Statement: The mission of the Mine Safety and Health Administration (MSHA) is to administer the provisions of the Federal Mine Safety and Health Act of 1977 (Mine Act) and to enforce compliance with mandatory safety and health standards as a means to eliminate fatal accidents; to reduce the frequency and severity of nonfatal accidents; to minimize health hazards; and to promote improved safety and health conditions in the Nation’s mines.

For more information, please visit MSHA’s website at: http://www.msha.gov