VorTEQ™ 100

Active Diesel Particulate Filter (ADPF) Features

- Active Diesel Particulate Filter (DPF) system designed to control particulate matter emissions from off-road diesel engines (in construction, material handling and mining applications) using a burner for periodic regeneration

- Not dependent on variations in exhaust gas temperature - ideal for cold engine applications

- Sulphur level tolerable, also compatible with ultra-low sulphur diesel (ULSD) and B20 biodiesel blend (20% biodiesel by volume)

- Onboard display with real-time analytics. Real-time display of DPF status, back pressure, temperatures, regeneration schedule, and vital performance statistics

- Alerts operator when regeneration is required (audible and visual alarms)

- Reliable and economical with a long filter life

- Engineered to install into a tight engine compartment

- No external power required to operate

- System typically provides 95%+ reduction in diesel particulate matter (PM) emissions and total elimination of black smoke

- DPF system performs regeneration during machine rest periods without interrupting operator’s work

VorTEQ™ 100 - Technology

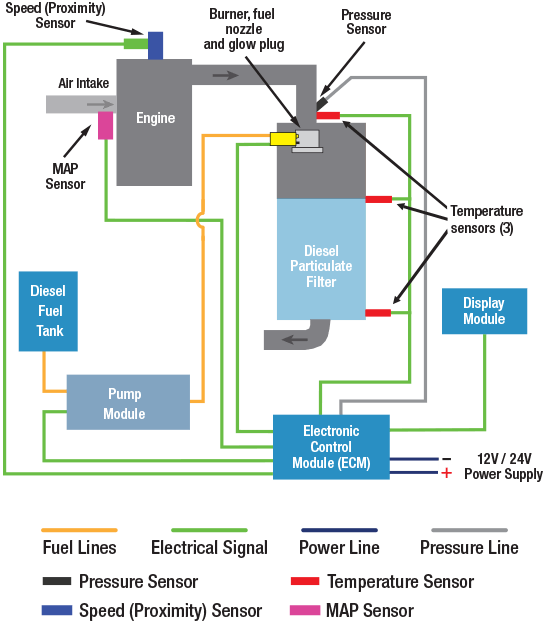

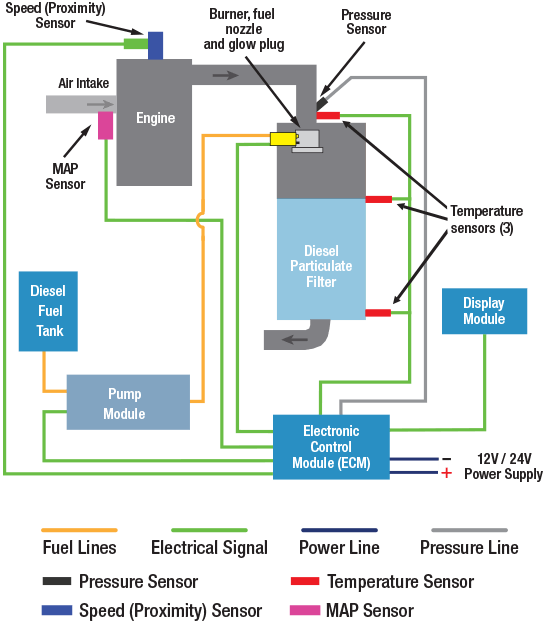

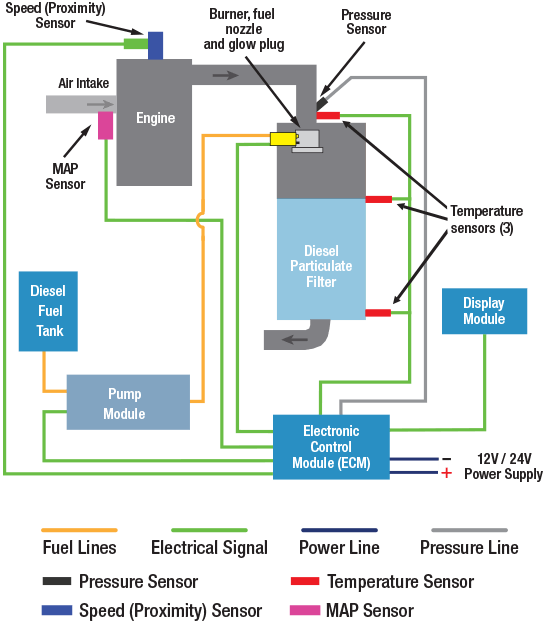

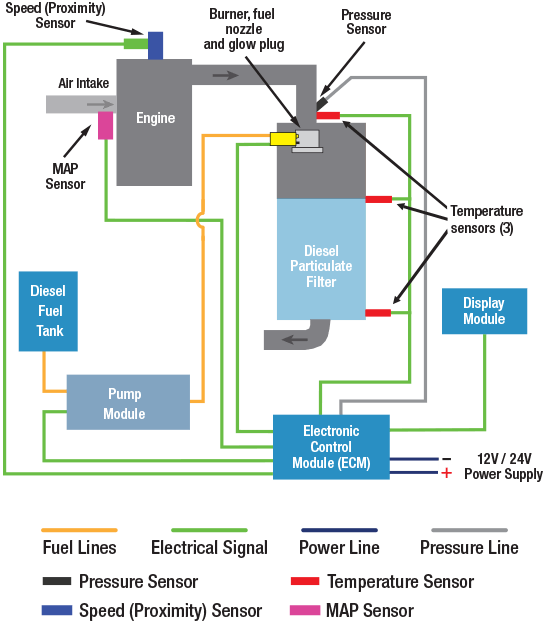

The Nett VorTEQ™ 100 Active Diesel Particulate Filter (ADPF) system uses a diesel fuel burner to heat and oxidize the Diesel Particulate Matter (DPM) that accumulates on a silicon carbide particulate filter monolith. A computerized monitoring system evaluates the level of soot in the filter and triggers regeneration (automatic mode) or alerts the machine operator (manual mode) when soot needs to be burned off. In both modes, the regeneration occurs during periods when the engine is idling.

Typical System Configuration

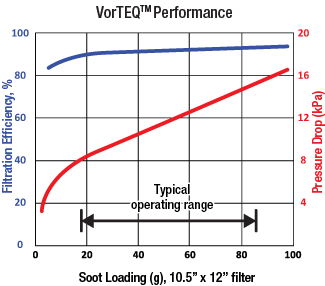

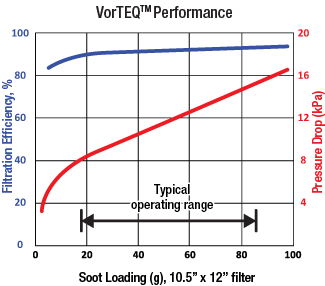

VorTEQ™ 100 - Performance

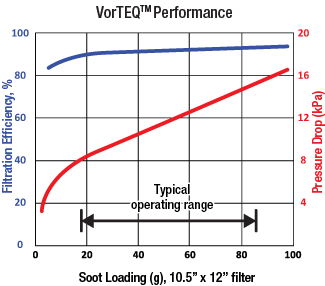

The particulate matter filtration efficiency of the active diesel filter typically exceeds 90%. The filtration efficiency of the elemental carbon fraction of diesel particulates (soot) is 95-99%. Due to the presence of a precious metals catalyst, the filter typically reduces 70-90% (depending on exhaust temperature) of Hydrocarbon (HC) and Carbon Monoxide (CO) emissions. There is no NO2 increase due to a special catalyst formulation. Typical exhaust gas pressure drop on an Active Diesel Particulate Filter (ADPF) system is between 7.5 and 15 kPa (30-50 in H2O).

VorTEQ™ 100 - Designs and Options

VorTEQ™ 100 systems are primarily used with light and medium-duty applications which typically require an OE muffler replacement design due to limited available space. Most designs are under-hood, retaining the equipment's factory appearance and operator sightlines.

Universal-fit designs are also available for applications with a suitable mounting location. Standard sizes and power ratings are shown below. Please contact us for sizing of particular engines and applications before ordering.

Nett VorTEQ™ 100 Active Diesel Particulate Filters (VX)

| Max. Engine Power | ||

| Model | hp | kW |

| VX502 | 33 | 25 |

| VX503 | 43 | 33 |

| VX504 | 54 | 41 |

| VX705 | 75 | 56 |

| VX707 | 94 | 71 |

| VX709 | 113 | 85 |

| VX910 | 135 | 101 |

| VX913 | 162 | 121 |

| VX1011 | 147 | 110 |

| VX1014 | 184 | 138 |

| VX1017 | 221 | 165 |

| VX1116 | 211 | 158 |

| VX1120 | 254 | 190 |

| VX1326 | 338 | 253 |

VorTEQ™ 100 - Technology

The Nett VorTEQ™ 100 Active Diesel Particulate Filter (ADPF) system uses a diesel fuel burner to heat and oxidize the Diesel Particulate Matter (DPM) that accumulates on a silicon carbide particulate filter monolith. A computerized monitoring system evaluates the level of soot in the filter and triggers regeneration (automatic mode) or alerts the machine operator (manual mode) when soot needs to be burned off. In both modes, the regeneration occurs during periods when the engine is idling.

Typical System Configuration

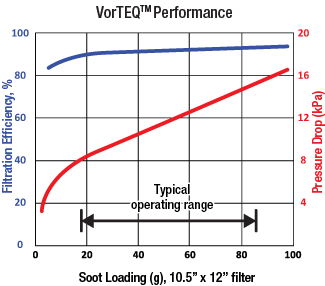

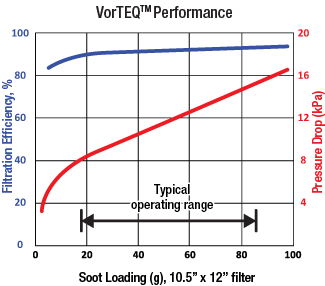

VorTEQ™ 100 - Performance

The particulate matter filtration efficiency of the active diesel filter typically exceeds 90%. The filtration efficiency of the elemental carbon fraction of diesel particulates (soot) is 95-99%. Due to the presence of a precious metals catalyst, the filter typically reduces 70-90% (depending on exhaust temperature) of Hydrocarbon (HC) and Carbon Monoxide (CO) emissions. There is no NO2 increase due to a special catalyst formulation. Typical exhaust gas pressure drop on an Active Diesel Particulate Filter (ADPF) system is between 7.5 and 15 kPa (30-50 in H2O).

VorTEQ™ 100 - Designs and Options

VorTEQ™ 100 systems are primarily used with light and medium-duty applications which typically require an OE muffler replacement design due to limited available space. Most designs are under-hood, retaining the equipment's factory appearance and operator sightlines.

Universal-fit designs are also available for applications with a suitable mounting location. Standard sizes and power ratings are shown below. Please contact us for sizing of particular engines and applications before ordering.

Nett VorTEQ™ 100 Active Diesel Particulate Filters (VX)

| Max. Engine Power | ||

| Model | hp | kW |

| VX502 | 33 | 25 |

| VX503 | 43 | 33 |

| VX504 | 54 | 41 |

| VX705 | 75 | 56 |

| VX707 | 94 | 71 |

| VX709 | 113 | 85 |

| VX910 | 135 | 101 |

| VX913 | 162 | 121 |

| VX1011 | 147 | 110 |

| VX1014 | 184 | 138 |

| VX1017 | 221 | 165 |

| VX1116 | 211 | 158 |

| VX1120 | 254 | 190 |

| VX1326 | 338 | 253 |

Downloadable Documents

VorTEQ™ 100 Brochure (Off-road)VorTEQ™ 100 Folleto (Español)VorTEQ™ 100 Fact Sheet

Photo Gallery